EZZY The Flight V2 wing 2025

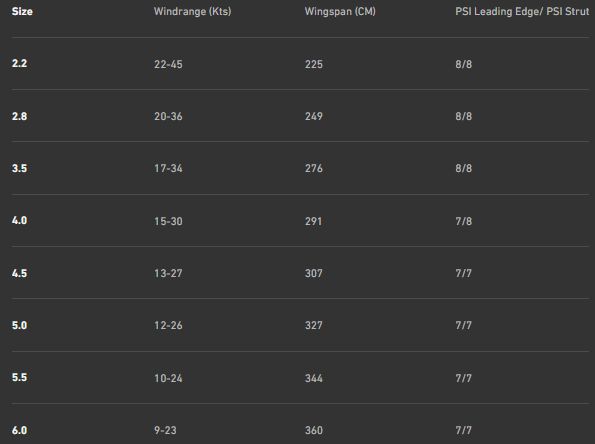

Kód: 1247/2.2 1247/2.6 1247/3.5 1247/4.0 1247/4.5 1247/5.0 1247/5.5 1247/6.0 Zvolte variantuDetailní popis produktu

**** obsah balení EZZY wingu : EZZY wing s batohem, 2 madla, leash a pumpa Naish Airmax2 ( bez pumpy bude cena snížena o 1.000,-Kč ).

AKTUÁLNÍ PROMO AKCE : KARBONOVÉ RÁHNO V CENĚ WINGU ( na vyžádání )

Nabízíme pozici team rider pro EZZY wing - testování, recenze nebo zakoupení wingu za nižší cenu.

EZZY Flight v2

Quiet and Tensioned Profile

Our EZZY v.2 wing has undergone major changes from our v.1. :

• A deeper, more draft forward profile improves stability, upwind pointing and low-end power.

• New W-80, warp orientated cloth used on the trailing edge has 40% less stretch than standard canopy fabrics. This prevents trailing edge flutter and greatly increases the longevity of the wing.

I• New, W-50 canopy cloth is a lighter version of the W-80 and is used for the main canopy.

• We invented a system we call the “Strut Loop” to improve the strut-to-canopy connection. The Strut Loop locks the canopy to the strut, which improves stability and overall performance.

• New radial seams reduce stretch and flutter by aligning the load paths at the back of the canopy.

• The trailing edge stabilizers are aligned perpendicular to the trailing edge to better resist flutter.

• New light weight radial canopy patch aligns the load at the end of the strut to prevent stretch.

• Lower leading edge handle improves flagging and makes the wing neutral for wave riding.

• Available soon: a retrofittable full boom. This will allow you to swap out the two handles for a single boom.

Lightweight, ergonomic handles match your wrist angle so you are able to relax your arms.

Our low stretch dacron is the best in its class in terms of stretch, firmness and durability.

Our 50 g/m² woven polyester ripstop canopy is strong, lightweight and low stretch.

Surgical grade, 100 micron bladder material is the best in the industry.

Separate leading edge and strut valves allows for different air pressures between the strut and leading edge. This produces a stiffer feeling wing and it also gives you the added security that you will always be able to make it back to the beach in case of a mishap.

Vnější průměr ventiů je 20,3mm ( 51/64'').

EZZY Wing boom

EZZY Wing V2

How to pack EZZ Flight wing

strut loop on the Ezzy Flight V2 Wing

Buďte první, kdo napíše příspěvek k této položce.

In 1983 David Ezzy made his first windsurfing sail under the Ezzy Sail black and white eagle logo. He started his custom sail business on Maui in an old shed that has since become a sleek design loft.

Back then, custom sails were the means to success for every serious sailor and Ezzy Sails led the sailing revolution. Ezzy made sails that were renowned for their “Hookipa” traits: strength and power.

In 1985, North Sails Windsurfing hired Ezzy to create their wave sail line and within two years Ezzy was in charge of all North’s lines including race sails for World Cup champion Stephan Van den Berg. In addition to the North Sails logo, the sails bore either the Ezzy logo or David Ezzy’s name on them. Production and profits rose under David Ezzy’s leadership. Ezzy became a Board member of North Sails Windsurfing in 1991.

The early nineties saw the sale of the German-based North Sails Windsurfing and new management took over the head office in Germany and at the factory in Sri Lanka. Ezzy tried to maintain his close involvement in the operation of the factory, but cost-cutting decisions began to take precedence over sail quality and even took precedence over the human rights of the Sri Lankan factory workers. The conflict over the treatment of workers vs. corporate profits reached a head in the summer of ’92, when upon arriving at the factory to put his designs into production, Ezzy found the air in the factory to be filled with the fumes of toxic spray glue. His attempts to help the workers by notifying management and North Sails’ owners, sending for product specifications from the glue manufacturer, brainstorming ideas for a construction of air vents to carry out the fumes, were all met with a curt, “mind your own business”: the 50 gallon drums of spray glue would stay and David Ezzy resigned in protest.

David visited other sail lofts in Sri Lanka and China with the idea of manufacturing Ezzy sails, but his early experience of having control over the quality at North Sails Windsurfing, made him realize that he would have to own his own factory to produce the high quality sails he wanted.

Meanwhile, his former colleagues at North Sails, the Sri Lankan nationals, organized themselves and approached David to start a factory of his own with them. In those bold days, the friends started a new venture with a shared ownership in Ezzy Sails Lanka. These top North Sails Winsurfing Sri Lankan managers and supervisors all became proud Ezzy Sails’ employees and part owners. The venture began in a small, old building in a town outside of the industrial zone.

Since high quality is David Ezzy’s most important consideration, employee quality-of-life is essential. The Ezzy factory today is housed in a 20,000 square foot, brand-new building with a large grass field out back for company cricket games. It is a safe, non-toxic work environment with state-of-the-art computer cutting machines, employee amenities such as a staffed kitchen, transportation, uniforms and a music sound system.